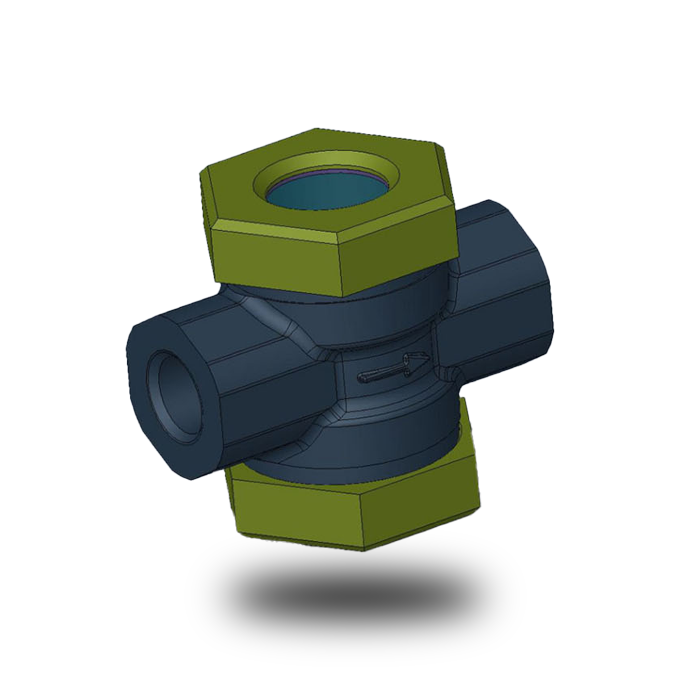

Forged SIGHT GLASSES, screwed cover

In steel, carbon steel, stainless steel and special materials

| CONSTRUCTION | Screwed cover |

| DESIGN STANDARD | ASME B16.34 |

| PRESSURE CLASS | 150#-300# |

| DIMENSIONS | from 1/4″ to 1″ |

| CONNECTIONS | Threaded: NPT -BSP Socket Weld (SW) Butt Weld (BW) Flanged: socket welded on flanges UNI – RF – RJ |

| MATERIALS | Carbon Steel Carbon Steel for Low Temperatures Stainless Steel Duplex and Super Duplex Alloy Steels Other Special Materials upon Request |

| GLASSES | Tempered Sodium-Calcium Glass (Tmax100°C) Tempered Borosilicate Glass (Tmax200°C) |

| FLOW INDICATORS | Floating Ball PPH or PTFE Fixed Blades PTFE Rotor (inline replaceable) |

| SPECIAL EXECUTIONS UPON REQUEST | |

General information on the product range. Please contact us for specific information.

U.S.V. for Your Supply of Flow Indicators

Sight glasses, or flow indicators, are essential for monitoring and observing the flow of fluids within pipelines and tanks.

We offer a wide range of materials for sight glasses, from standard steel to special alloys. Based on thermal resistance requirements, we equip these devices with tempered glass or borosilicate glass.

Whatever your operating environment, we can configure the product to ensure consistently high reliability.

The V300S series flow indicators, made of forged steel with threaded body/cover connections, are suitable for general-purpose applications.

They are designed with minimum wall thickness in compliance with ASME B16.34. Overthickness for corrosion allowances is provided.

Each sight glass undergoes hydrostatic testing by our quality department and is supplied with an EN 10204 3.1 certificate.